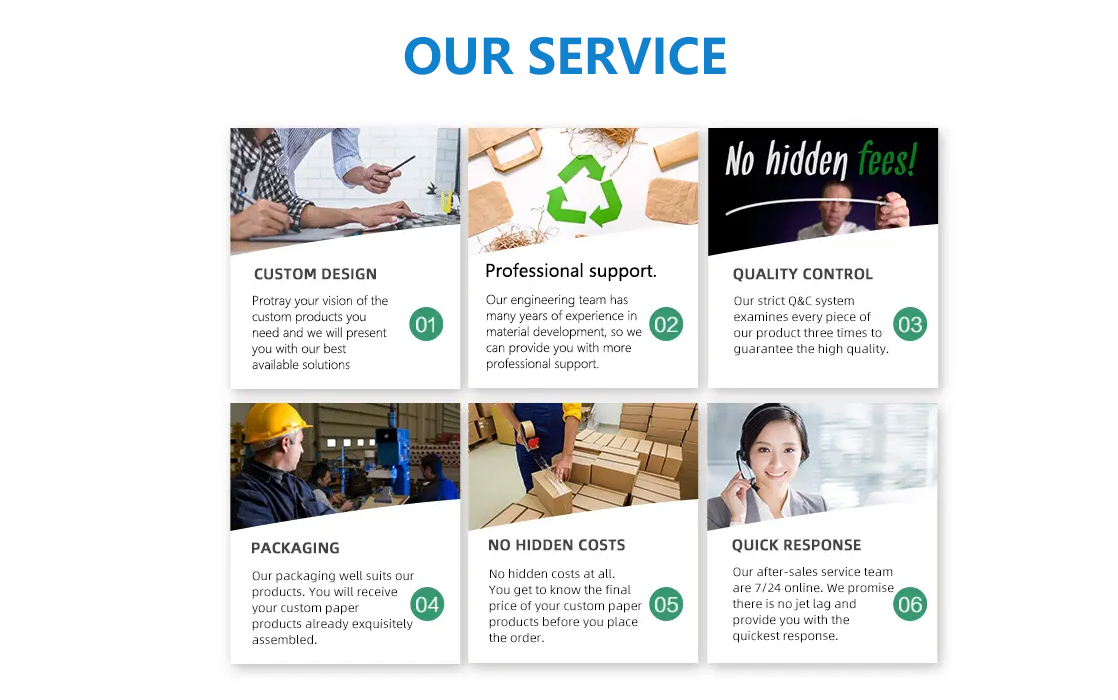

Kaunggulan

Résistansi oksidasi suhu luhur

résistansi korosi alus teuing

Alus lalawanan abrasion

Koéfisién luhur konduktivitas panas

Self-lubricity, dénsitas low

Karasa luhur

Desain ngaropéa.

Aplikasi

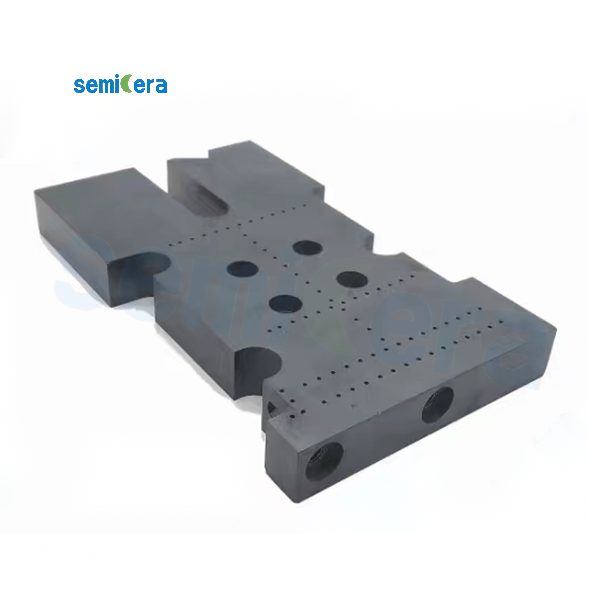

-Wear-tahan Widang: bushing, piring, sandblasting nozzle, siklon pinding, grinding tong, jsb ...

-Lapang Suhu Tinggi: siC Slab, Quenching Tube Tube, Radiant Tube, Crucible, Elemen Pemanas, Roller, Beam, Heat Exchanger, Cold Air Pipe, Burner Nozzle, Thermocouple Protection Tube, SiC boat, Kiln Car Structure, Setter, jsb.

-Silicon Carbide Semiconductor: SiC wafer boat, sic cuk, sic dayung, sic kaset, sic difusi tube, wafer garpu, nyeuseup piring, guideway, jsb.

-Silicon Carbide Seal Field: sagala jinis ring sealing, bearing, bushing, jsb.

-Photovoltaic Widang: Cantilever ngawelah, grinding Laras, Silicon Carbide Roller, jsb.

- Médan Batré Litium

Sipat Fisik SiC

| Harta | Nilai | Métode |

| Kapadetan | 3,21 g/cc | Tilelep-ngambang jeung dimensi |

| Panas spésifik | 0,66 J/g °K | Lampu kilat laser pulsa |

| Kakuatan flexural | 450 MPa 560 MPa | 4 titik ngalipet, RT4 titik ngalipet, 1300 ° |

| Kateguhan narekahan | 2,94 MPa m1/2 | Microindentation |

| Teu karasa | 2800 | Vicker urang, 500g beban |

| Elastis ModulusYoung urang Modulus | 450 GPa430 GPa | 4 pt ngalipet, RT4 pt ngalipet, 1300 °C |

| Ukuran gandum | 2 – 10 µm | SEM |

Sipat termal SiC

| Konduktivitas termal | 250 W/m °K | Métode flash laser, RT |

| Ékspansi Thermal (CTE) | 4,5 x 10-6 °K | Suhu kamar nepi ka 950 °C, silika dilatometer |

Parameter Téknis

| Barang | Unit | Data | ||||

| RBSiC(SiSiC) | NBSiC | SSiC | RSiC | OSiC | ||

| eusi SiC | % | 85 | 75 | 99 | 99.9 | ≥99 |

| eusi silikon bébas | % | 15 | 0 | 0 | 0 | 0 |

| Max suhu jasa | ℃ | 1380 | 1450 | 1650 | 1620 | 1400 |

| Kapadetan | g/cm3 | 3.02 | 2.75-2.85 | 3.08-3.16 | 2.65-2.75 | 2.75-2.85 |

| Buka porosity | % | 0 | 13-15 | 0 | 15-18 | 7-8 |

| Kakuatan bending 20 ℃ | Мpa | 250 | 160 | 380 | 100 | / |

| Kakuatan bending 1200 ℃ | Мpa | 280 | 180 | 400 | 120 | / |

| Modulus élastisitas 20 ℃ | Gpa | 330 | 580 | 420 | 240 | / |

| Modulus élastisitas 1200 ℃ | Gpa | 300 | / | / | 200 | / |

| konduktivitas termal 1200 ℃ | W/mK | 45 | 19.6 | 100-120 | 36.6 | / |

| Koéfisién ékspansi termal | K-1X10-6 | 4.5 | 4.7 | 4.1 | 4.69 | / |

| HV | Kg/mm2 | 2115 | / | 2800 | / | / |

Lapisan silikon carbide CVD dina permukaan luar produk keramik silikon carbide recrystallized tiasa ngahontal kamurnian langkung ti 99.9999% pikeun nyumponan kabutuhan palanggan dina industri semikonduktor.